Written by Marc Bolick

I jokingly tell people that I’m a “recovering engineer,” not because I’m in any way ashamed of being a gear head, but to demonstrate that anyone can learn to use the problem-solving approach of designers.

Before I learned to think like an engineer, I learned the scientific method—the mother of all problem-solving methodologies. Sprinkled into the mix came a concentration of psychology courses that sparked my interest in human behavior and management science. All this—combined with an early career in manufacturing, product management and consulting—circuitously led me to design thinking.

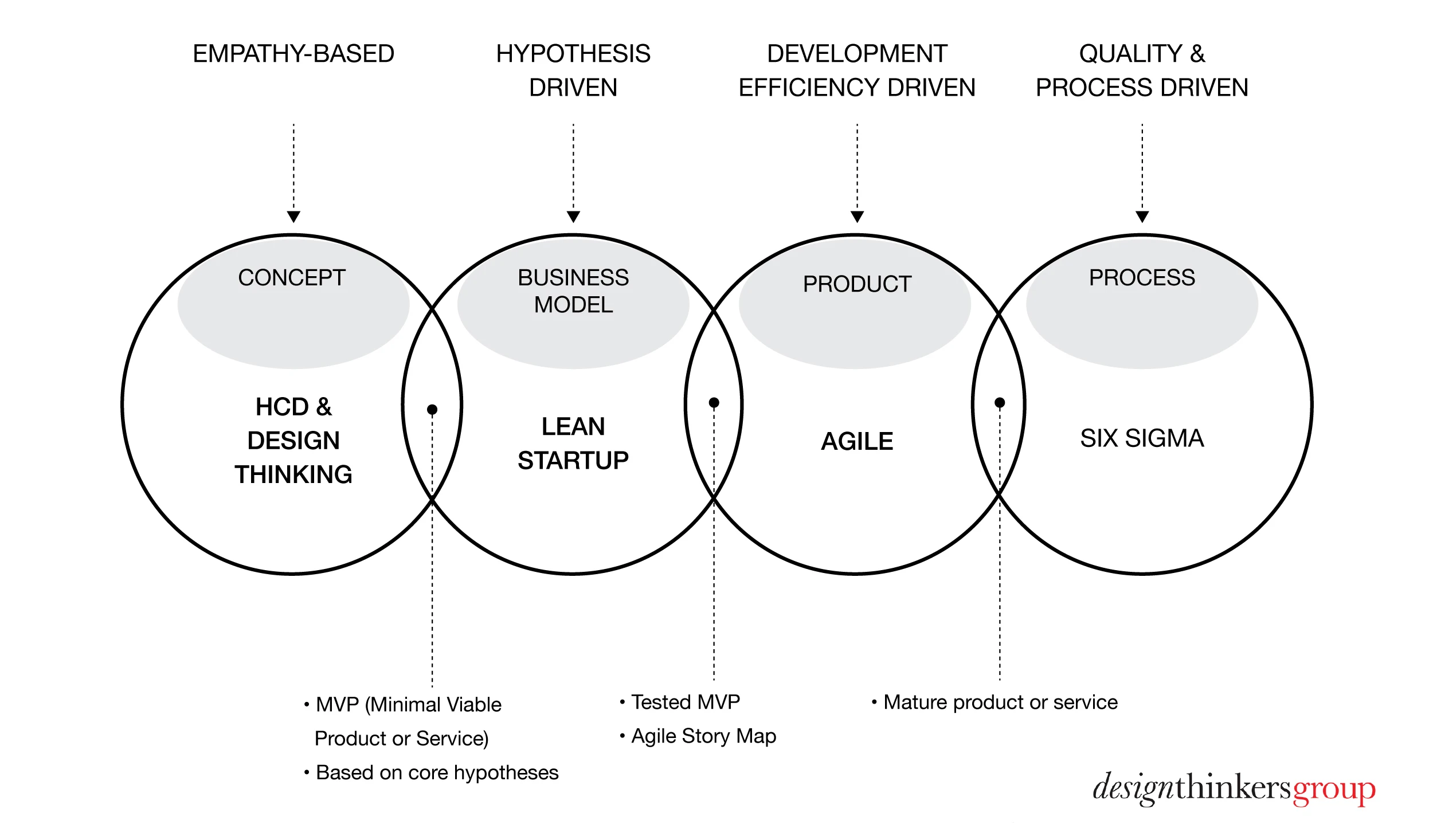

Very closely related to design thinking are lean startup, agile and (Lean) Six Sigma—all four carry some of the same problem solving genes and even overlap quite a bit. It can be difficult, though, to understand how each is defined and how they are different or similar.

Let me explain.

All are human-centric

Each of these ways of working is human-centered and responsive to customer needs.

- Design thinking builds empathy among the design team so that problem solving is based on the needs of the customer or end user.

- Lean startup identifies a core set of hypotheses around a business opportunity and tests that the customer value proposition can result in a viable product.

- Agile is an implementation framework that reduces the development cycle time so that products are more attuned to customer needs, allowing faster rollout of new features.

- (Lean) Six Sigma is a quality system that looks at the ‘voice of the customer’ and results in a product or process with a low level of defects, focused on delivering consistently reliable and high quality products.

Most are hypothesis driven

Fundamentally, all of these methodologies are about solving problems. Each approach addresses different types of problems and different parts of the lifecycle of a product or service. The one outlier is agile, which is less about solving problems in general and more about solving a very specific challenge: delivering products in a way that is efficient and responsive to both customer needs and the capacity constraints of the development team.

The problem solving trio—design thinking, lean startup and Six Sigma—share the assumption that you, the problem solver, do not know the answer to the problem. Rather, you have a hypothesis about the nature of the solution to the problem, and you need formulate a test to discover whether the solution is ‘correct.’ This hypothesis-driven nature is something we can all relate to from our high-school science classes.

All are iterative

Each of the four systems is about the process that teams follow, and the ways that they collaborate, at a particular part of the product or service lifecycle. Another common trait is that each process is iterative in nature.

Design thinking is often represented as some form of step-by-step process, but in fact it is highly iterative. Design teams will commonly move from customer research to developing insights—and back again to research in order to refine data—as they seek key opportunities to improve the customer experience.

Lean startup can take the outputs of the design thinking process and create a succession of tests to refine the business model. The core ideas, articulated as hypotheses, are refined through test-and-learn cycles until a minimum viable product (MVP) is validated.

Once the MVP is defined and refined, it can be developed in an agile manner and brought to market. Agile takes a product specification and breaks the development work into a set of iterations (commonly called sprints) that build up a product with more and more features and improvements (and bug fixes).

Six Sigma focuses on eliminating defects and waste in the way a product is delivered to customers (whether as a physical product or as a service). It also can be iterative in the sense that it strives to chip away at defects in a production process through cycles of improvement.

All are related and overlap

The other thing that ties these methodologies together is that they overlap one another. They can easily and happily co-exist inside an organization. Indeed, we often find that organizations seeking to upskill their operational excellence or IT teams are eager for them to adopt design thinking or lean startup.

Faced with an innovation challenge, your team can use design thinking to identify a set of needs, ideate and prototype to create a new business concept. You then need to prove that your concept truly meets the needs of a specific customer segment, and that the customer is prepared to part with their money to possess the product or experience the service offering. The concept MVP is developed, a business model is wrapped around it, and then the combination is systematically tested using lean startup techniques.

Once the MVP has been refined through iterative cycles of testing and learning, the design team hands off to a development team where the product gets built in an agile manner, starting with the MVP and building additional features based on rapid feedback from customers.

Finally, as the organization rolls out the new product or service and refines its processes for manufacturing or service delivery, (Lean) Six Sigma can be used to perfect the resulting products, improving service quality, taking out defects, and optimizing the margins of the product for the business.

None of this is easy

It’s no wonder that people get confused with these closely related methodologies. They are often referenced by people who have limited exposure to what they really mean in practice. Business literature and management hype tend to get people excited about one or another method and they become the latest shiny object that leadership pushes to improve results.

Worse still, to develop mastery of any of these methods requires years of training, lots of trial and error, and no small amount of investment in time and treasure. Once someone becomes proficient in one methodology, they are likely to look on something new or different with great suspicion, especially since there are such important similarities between the different approaches.

So, which one should you use?

The answer, of course, is that it depends on what you are trying to do.

- If you’re looking to optimize the quality and delivery of something, Six Sigma is the best way to go. It uses powerful statistical tools and a structured process to get defects out.

- If you want to find innovative solutions to a complex problem or redefine customer experience, design thinking is your best bet to get started.

- Once you have a concept for a new way to wow your customers, use lean startup to test and iterate both product and business model.

- For developing products in a continuous improvement manner that fits your development team’s capacity, use agile—it’s way better than ‘waterfall’ for most organizations.

It’s likely you have someone in your organization who does each of these things. Don’t be intimidated by the fancy names. It is easy enough for you to get a basic idea of what each one does and the value it provides to your organization. And, if you need to know more, just ask an expert to explain, because most experts love to tell you what they know!